Using Computer Vision to innovate label production at EE Labels

In the textile factory of EE Labels, thousands of product labels are being produced and printed every day. With such a high volume of production, even the smallest error can have significant consequences. The challenge? Ensuring that production remains flawless while catching mistakes before they lead to waste or delays.

The need for innovation

Traditionally, detecting production errors required human operators to keep a close eye on the machines. However, with multiple machines running simultaneously, it is nearly impossible for a single operator to monitor everything at once. Even minor misprints or alignment issues could go unnoticed, leading to defective labels and a delayed production process.

Recognizing this challenge, we implemented a computer vision approach—a powerful tool that could speed up the operations. By implementing this detection system, we aimed to flag mistakes the moment they occurred, allowing operators to intervene immediately and prevent further errors.

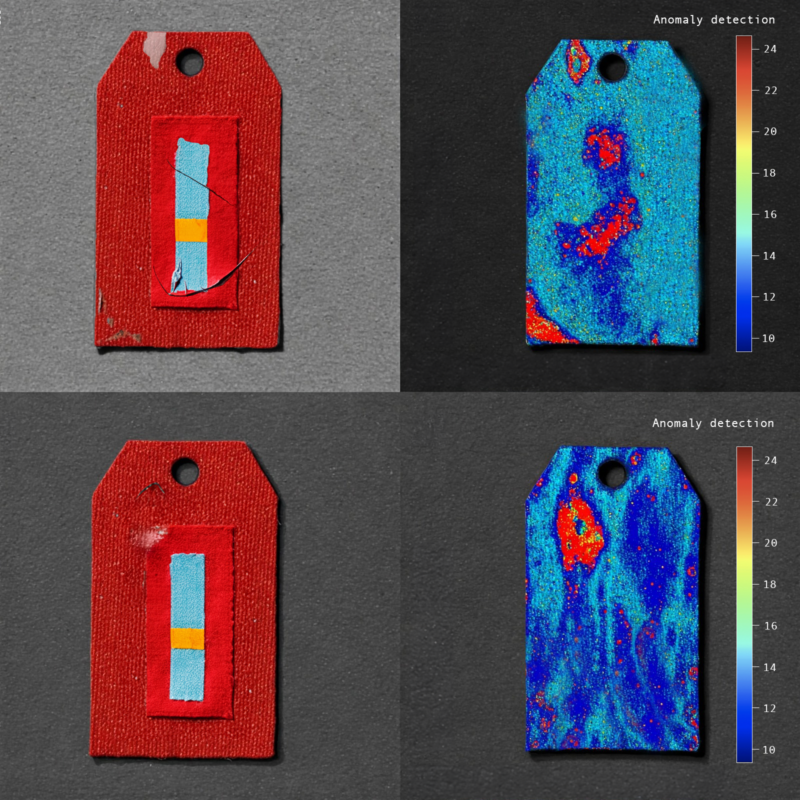

Anomaly detection method

Unlike traditional supervised computer vision approaches, which needs to be trained with both good and bad examples, our approach is different—we only use perfect labels to teach the system what “normal” looks like. The model then learns the patterns, textures, and details of high-quality labels. Once trained, it automatically spots anything that looks unusual or different—like misprints, or missing details—without ever having seen a defective label before.

This means our approach has several advantages over the traditional supervised approach:

✅ No need to collect or manually label bad examples of the product

✅ Faster setup and easier scaling

✅ Reliable, automatic quality control

The fusion of traditional craftsmanship with AI technology is the future of manufacturing, and we’re happy be part of this!