Manufacturing

AI solutions within Manufacturing

The manufacturing industry relies heavily on precision, efficiency, and quality control making it an ideal domain for computer vision applications.

Computer vision can significantly increase productivity by automating visual inspection tasks, detecting defects, and ensuring consistency in production.

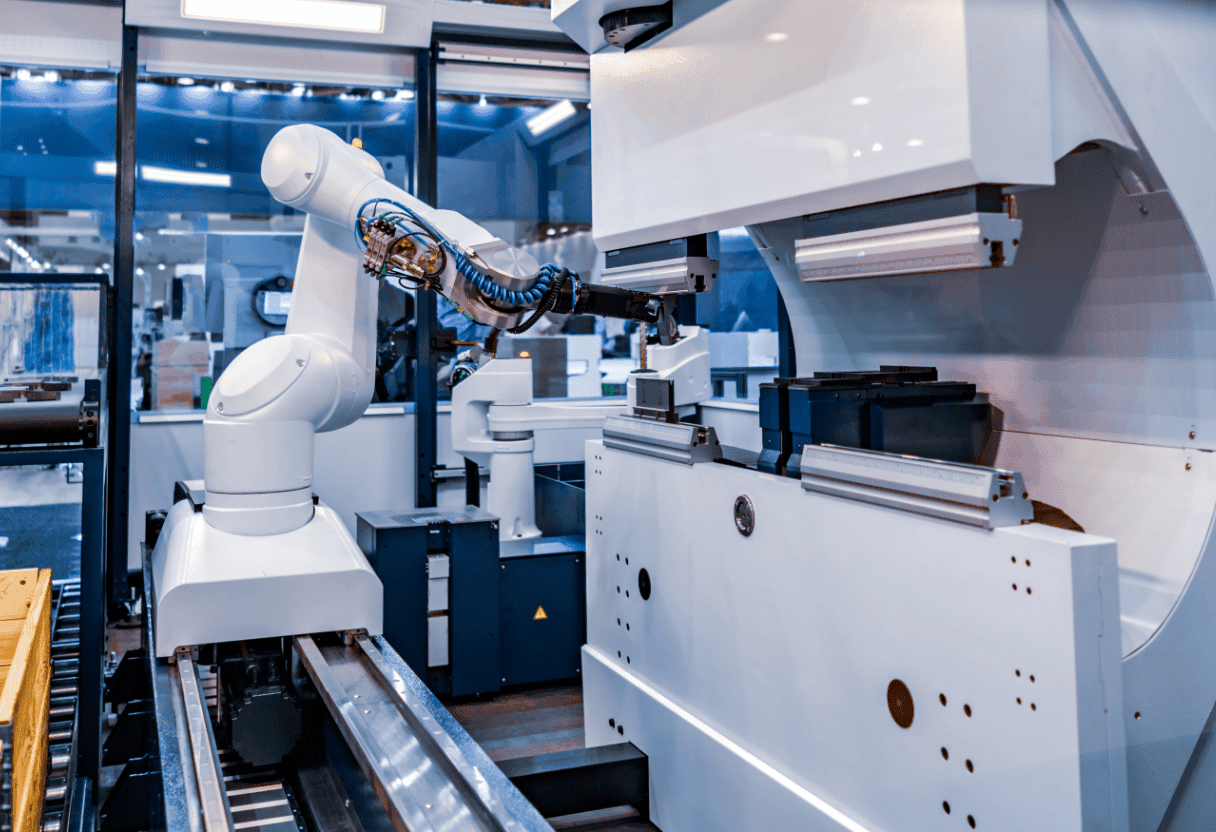

It can monitor assembly lines in real-time, verify product dimensions, identify surface flaws, and even guide robotic systems for precise operations like welding or packaging.

It can monitor assembly lines in real-time, verify product dimensions, identify surface flaws, and even guide robotic systems for precise operations like welding or packaging.

Multisensor AI applications within Manufacturing

Explore the range of solutions we offer

Defect detection

Identify flaws in products during production. This allows for faster quality control by automatically flagging defective items for removal or rework.

Automation

Automated systems can be created to perform tasks such as sorting, assembling, and quality checking with high precision.

Productivity

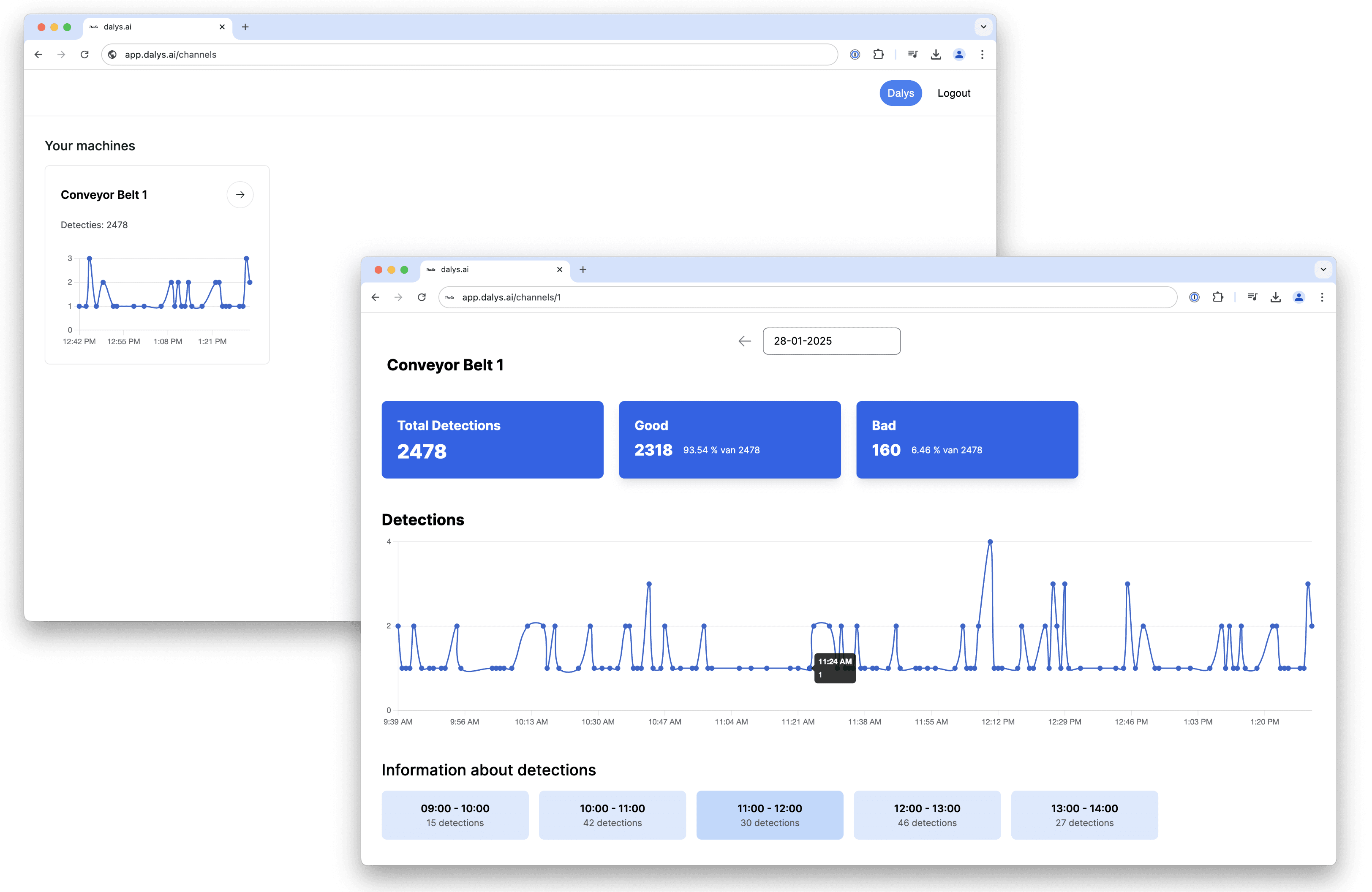

Enable real-time monitoring and automate tasks, reducing human intervention. This results in faster processes and higher overall productivity.

Applications within the Manufacturing Industry

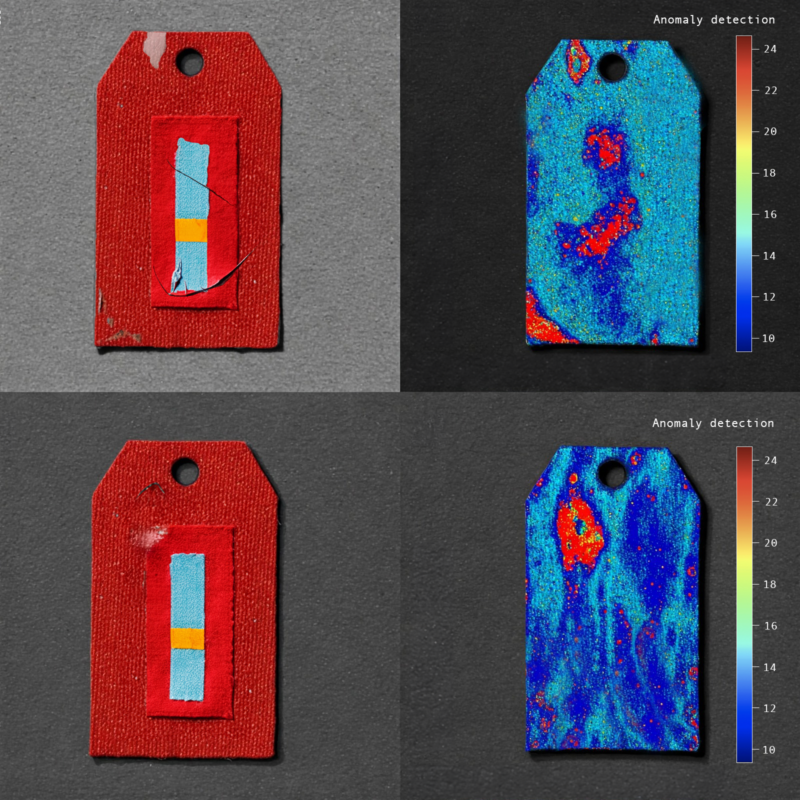

Integrate computer vision into your production line to automatically detect defects like scratches, dents, or irregular textures in real time. This system helps automate the manufacturing industry by enabling real-time quality control —reducing manual labor and increasing productivity.

Leverage advanced computer vision and unsupervised learning to automatically detect product anomalies—training exclusively on perfect products. No need for labeled defect data. The system is highly scalable and easily adaptable across different production lines.

Integrate conditional monitoring of your valuable assets with multivariate sensor data. Our AI technology is able to detect deviations on individual sensor level and thereby identify early signs of degradation or failure. This system enables proactive maintenance, minimizing costly repairs and preventing major breakdowns. It automatically raises alarms and notifications when detecting anomalous trends.

Insights

By reducing human error and enhancing speed, computer vision not only boosts productivity but also ensures higher quality standards, reduced labour costs and improved customer satisfaction.

Talk to an expert

Let’s find out what we can mean for you! We’re always open to have a chat.