Solutions

Computer vision

Computer vision, integrated as a self-operating system, drives automation, improves quality control, and reduces manual labor across various industries.

Defect detection

Computer vision can significantly increase productivity by automating visual inspection tasks, detecting defects, and ensuring consistency in production. By automated defect detection, manufacturers can improve product quality, minimize waste, and lower costs associated with manual inspections and rework. Once a defect is detected, an actuator can be triggered to automatically remove the faulty product, which automates the process and minimizes human intervention.

Computer vision applications in different fields

Examples of how computer vision could be implemented.

Computer vision applications in different fields

Examples of how computer vision could be implemented.

Surface defects

Identify flaws such as scratches, dents, or irregular textures with precision.

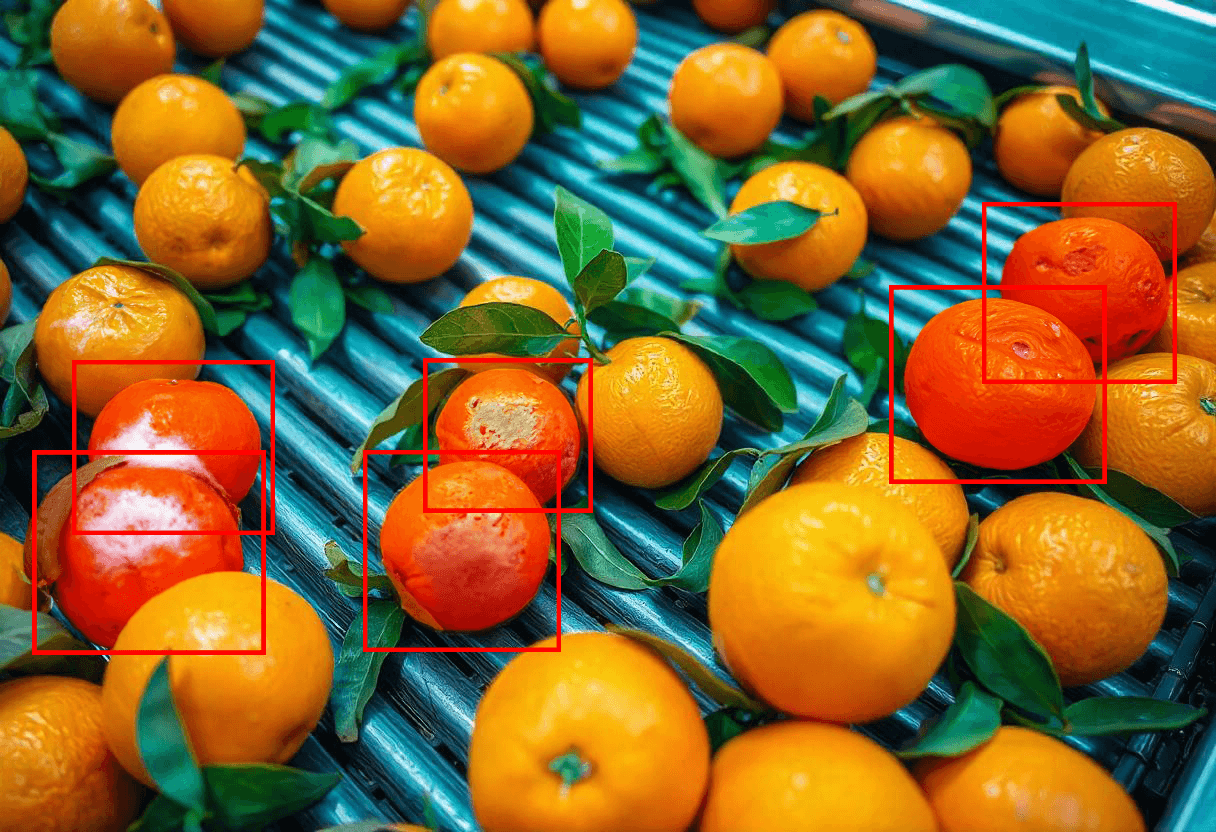

Low-quality fruits

Detect the color, texture, size, and shape of the fruits during production process.

Drone vision for agriculture

Hyperspectral cameras detect valuable soil and plant health metrics with great precision.

Count humans in public areas

Provide insights for urban planning and infrastructure development.

Key benefits of Computer vision

Quality

Identify flaws in products during production. This enhances higher quality products and faster quality control by automatically flagging defective items.

Automation

Automated systems can be created to perform labour intensive tasks such as sorting, assembling, and quality control with high precision.

Productivity

Enable real-time monitoring and automated tasks, reducing human intervention. This results in faster processes and higher overall productivity.

Real-time insights

All information at your fingertips. Get real-time insights into your operations in the Dalys platform.

With detailed analytics, you can easily identify and analyze the types of defects occurring on your production line.

With detailed analytics, you can easily identify and analyze the types of defects occurring on your production line.

Hardware installation

Dalys provides a fully integrated solution, removing the need for client expertise in hardware. Our team manages the hardware setup, including the installation of cameras, sensors, and edge devices at the specified location.

Talk to an expert

Let’s find out what we can mean for you! We’re always open to have a chat.